"Can you engrave coasters with a laser?" Absolutely – yes!

In this guide, we'll show you everything you need to know about laser engraving coasters . We'll explain exactly what it is, how it works, its advantages, and guide you step-by-step through the process to create your own engraved coasters from slate, cork, or wood.

This article contains:

- Part 1: What is coaster laser engraving and which machine is needed?

- Practical example: Engraving slate coasters with a laser in 5 steps 💡

Part 1: What is coaster laser engraving and which machine is needed?

1.1 What is coaster laser engraving?

A coaster is a small, flat accessory used to protect table surfaces from moisture or heat damage caused by glasses and cups. Coasters are often made of materials such as cork, wood, stone, or metal and are available in many shapes, sizes, and designs to suit different interior styles.

Laser engraving of coasters means using a laser to apply individual designs to the surface of the coaster. Whether slate, cork, wood, metal, or other materials – laser engraving is always a great way to creatively design coasters!

1.2 How does laser processing of coasters work?

Laser engraving of coasters uses a powerful laser beam to burn text or designs into the surface of the coaster. The localized heating and vaporization process creates permanently visible lettering, images, or patterns.

1.3 Coaster laser engraving machine:

To start laser engraving coasters , you need a laser engraver. This device is crucial as it simplifies the engraving process and ensures precise, long-lasting results.

Many people ask themselves: Which machine do I need to engrave coasters?

Diode lasers are indeed ideal for laser engraving coasters at home or in small businesses. If you value portability, ease of use, and good value for money, a diode laser is the best choice.

💡 Case study: Engraving slate coasters with a laser in 5 steps

Checklist for preparing slate coaster engraving:

- Engraving material: Slate plate

- Engraving machine: Laser engraver

- Engraving design: text, logo, images, patterns, etc.

Can you laser engrave slate coasters? Yes, absolutely! The process is straightforward. And how long does it take to engrave a slate coaster? Don't worry – with these 5 easy steps, you'll have your engraved slate coaster ready in just a few minutes!

Step 1: Choose your material – slate slab

Choosing the right material is crucial for the quality of the laser engraving. Different materials require specific laser settings to achieve precise results. Furthermore, ensure that the material is laser-compatible to avoid safety risks.

In this guide, we'll use a slate slab as an example!

Step 2: Choosing the right laser engraving machine for slate coasters

We recommend the LaserPecker 5 (LP5) . The LP5 is a dual laser that delivers excellent results on slate and can evenengrave deeply into stone . Thanks to its embossing function, you can create impressive 3D effects on slate or wood .

*Besides the LP5, the LP4 , LP3 , and LP2 are also suitable. All deliver good results for engraving coasters.

Engraving slate coasters with the LaserPecker LP3

Engrave cork coasters with the LaserPecker LP2

Step 3: Prepare your engraving design

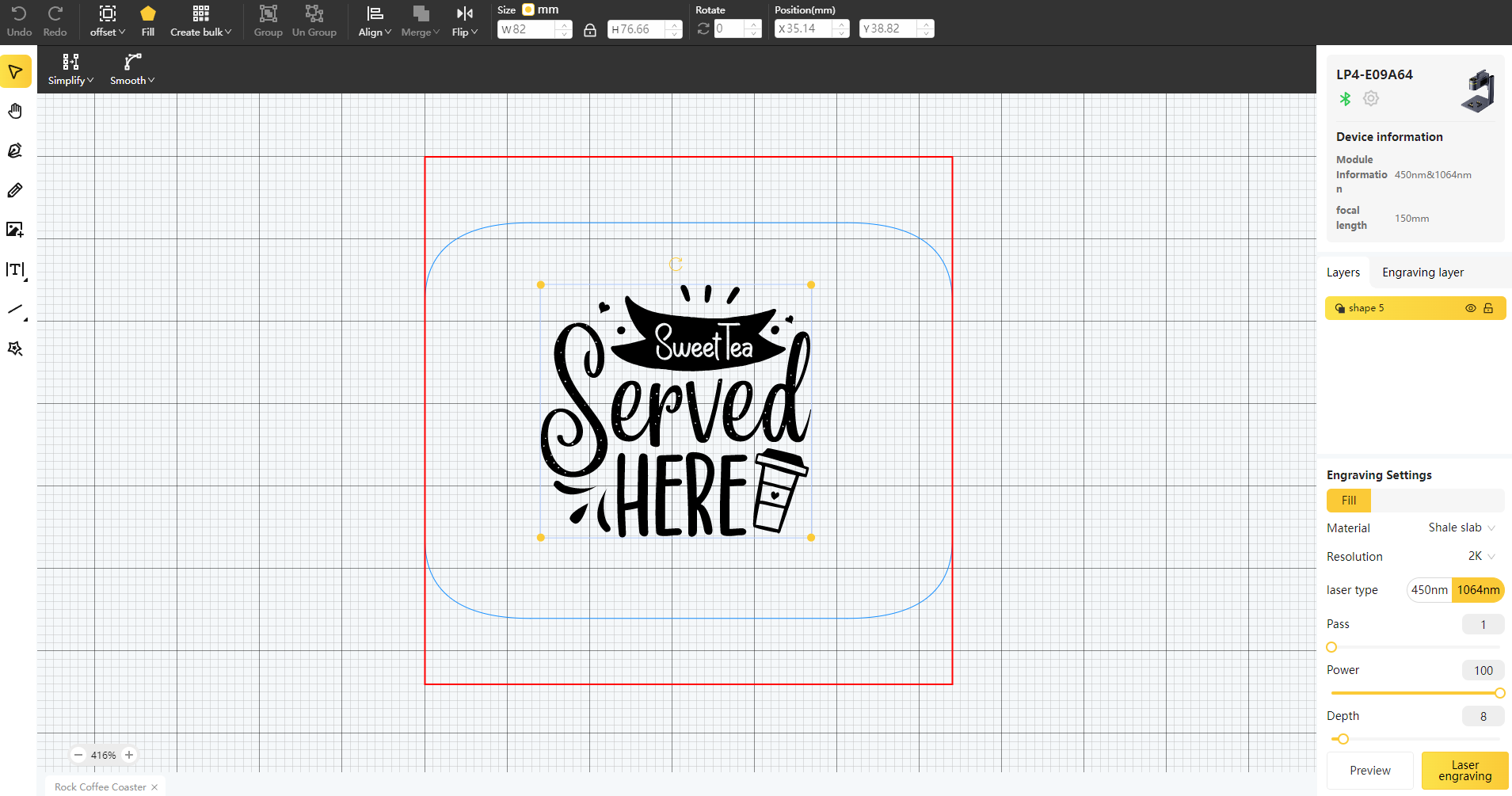

Use the LaserPecker design software to create or import your desired design for the slate coaster. Pay attention to size, shape, and details such as lettering or patterns.

Step 4: Setting up the laser engraving machine

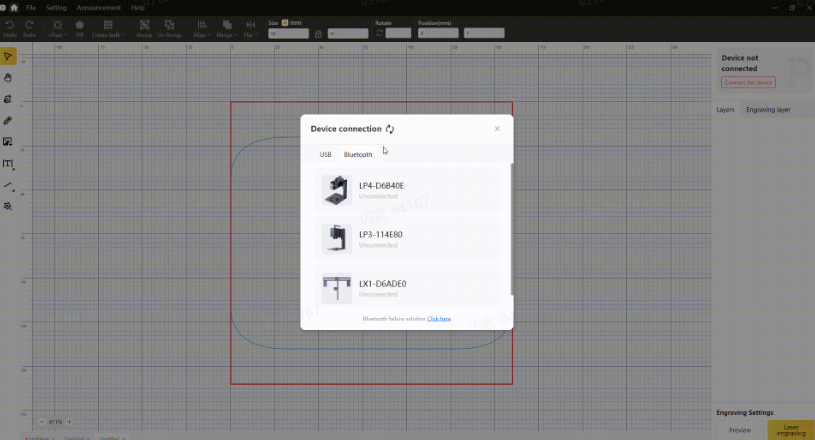

Turn on the laser engraver and connect it to your computer or smartphone via USB, Bluetooth or Wi-Fi.

Then open the software and load your design.

Activate "Preview Mode" to correctly focus the laser. Place the coaster in the work area and check the position and size of your design. Adjust them if necessary.

Open the laser settings in the software and adjust parameters such as power, depth and resolution to suit the material and design.

You might be wondering: "How much laser power is needed for slate coasters?" Here's the recommendation:

For optimal results with the LP5, we recommend: 10W 1064nm fiber laser, 100% power, 20% depth and 1 pass.

Further recommended LaserPecker settings for all models (LP1, LP2, LP3, LP4, etc.) can be found in the material table.

Step 5: Now start engraving your coaster

Double-check everything to avoid mistakes. Then press the start button and watch as the laser brings your design to life. Keep an eye on the process, and your coaster will be finished!

When engraving, it is best to wear safety glasses or use a protective cover, as the laser beam can be harmful to your health.

Please also remember that engraving can produce smoke or gases. An air purifier or respirator is therefore recommended.

Conclusion

In summary, laser engraving of coasters offers a unique opportunity to add personal touches and implement creative design ideas. Precise laser technology allows slate coasters to be decorated with detailed patterns, text, or messages, further enhancing their appearance and individuality.