"Has anyone ever cut wood with a laser?"

This guide covers laser cutting wood – from the basics to the finished project! We also present a case study on laser cutting a wooden lamp . Let's embark on this exciting adventure together!

This article contains:

Part 1: Overview of laser cutting wood

1.1 What is wood laser cutting?

Laser cutting of wood , also known as laser cutting of wood , is a precise method for transforming wood into various shapes, designs, letters, or individual parts. With laser cutting of wood, your creative ideas can be effortlessly turned into impressive works of art.

1.2 How does laser wood cutting work?

"Can you cut wood with a laser?" Yes! Laser wood cutting uses a powerful laser beam that is focused onto the wood surface. The intense heat of the laser cuts the wood along the beam path, producing clean, precise cuts.

Because the laser beam is controlled by computer software, even complex and intricate designs can be cut with high precision. Compared to other woodcutting methods, this results in smooth edges and minimal kerf, ideal for fine patterns and delicate shapes.

1.3 Which wood laser engraving machine is needed?

To cut wood with a laser, you need a wood laser engraving machine that makes the cutting process efficient and delivers precise results. There are various laser cutters on the market (e.g., diode lasers, CO2 lasers, or fiber lasers), and the question often arises: "Which laser is best suited for laser cutting wood?" or "Which machine do I need to cut wood?"

The choice depends on your individual needs. For home or small wood laser cutting projects, diode lasers like the LP5 and LP4 are ideal. These diode laser cutters for wood are user-friendly and cost-effective compared to other wood cutting devices.

💡 Case study: Cutting a wooden lamp with a laser in 5 steps

Preparation list for laser cutting wood:

- Material: 3 mm plywood sheet

- Machine: Diode laser cutter

- Design: Patterns, letters, shapes, etc.

The process of laser-cutting a wooden lamp is simple. How long does it take to laser-cut wood? Don't worry – just follow these 5 steps, and your wooden creations will be finished in minutes!

Step 1: Select material – plywood sheet

Choosing the right material is crucial for laser cutting wood . Different types of wood require specific laser settings for precise cuts. Also, ensure the wood is laser-safe to avoid safety hazards.

In this tutorial, we will use a case study on laser cutting a lamp from wood !

Step 2: Selecting the right laser cutter for wood

Here we recommend the LaserPecker 4 (LP4) , which is ideal for laser cutting wood .

*In addition to the LP4, you can also choose the LP5 , which also offers excellent performance for laser cutting wood (up to 20 mm basswood) and is suitable for wood embossing .

Alternatively, the LaserPecker LX2 is ideal for larger projects. With powerful 20W/40W/60W diode laser options, it can easily cut thicker materials – perfect for large-area laser cutting of wood .

Step 3: Prepare your design

Use the LaserPecker Design App/Software or other graphics tools like Photoshop to create or import shapes or designs for the wood surface. Consider size, shape, and other details.

*You can also visit LaserPecker CraftZone to find inspiration or to buy laser-cut wood files online .

Step 4: Setting up the wood laser engraving machine

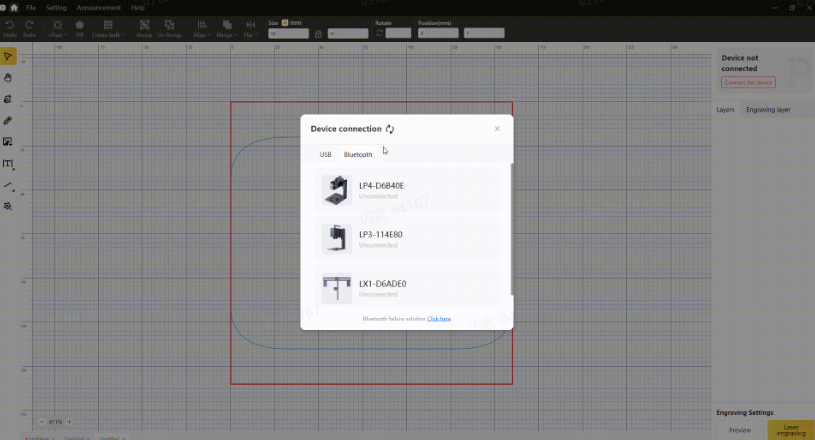

First: Turn on your laser cutter and connect it to your computer or mobile device via the appropriate interface (Wifi, USB, Bluetooth, etc.).

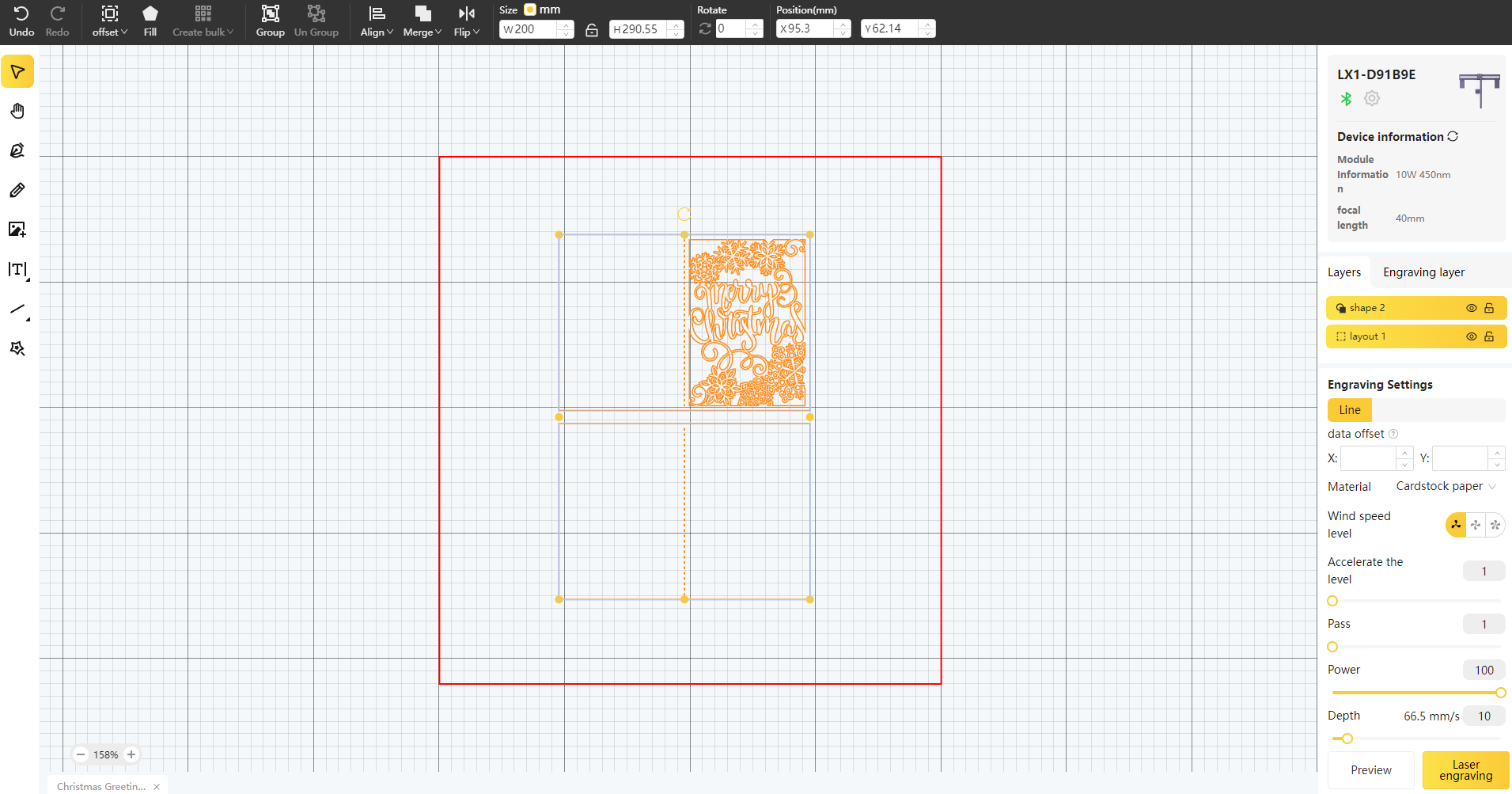

Second: Open LaserPecker Design Space and upload your design. (JPG/PNG/G-code/SVG etc. are supported.)

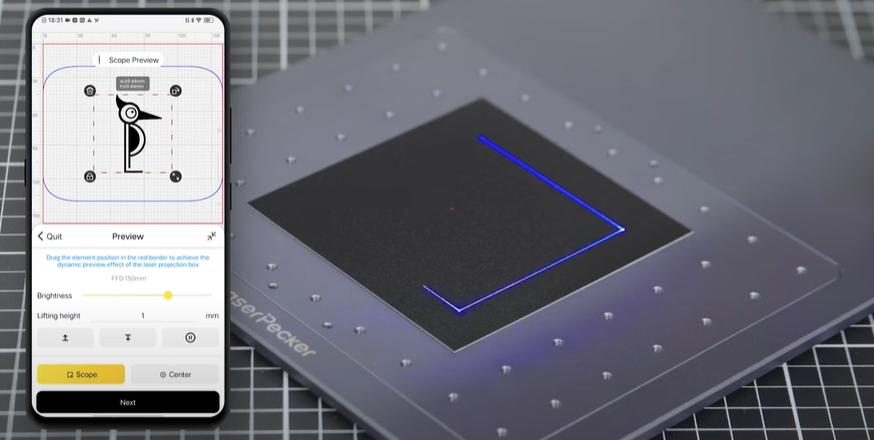

Third: Place the wood in the work area, activate preview mode and ensure that the laser is correctly focused.

Fourth: Check if the design fits the wooden surface. If necessary, adjust the size and position.

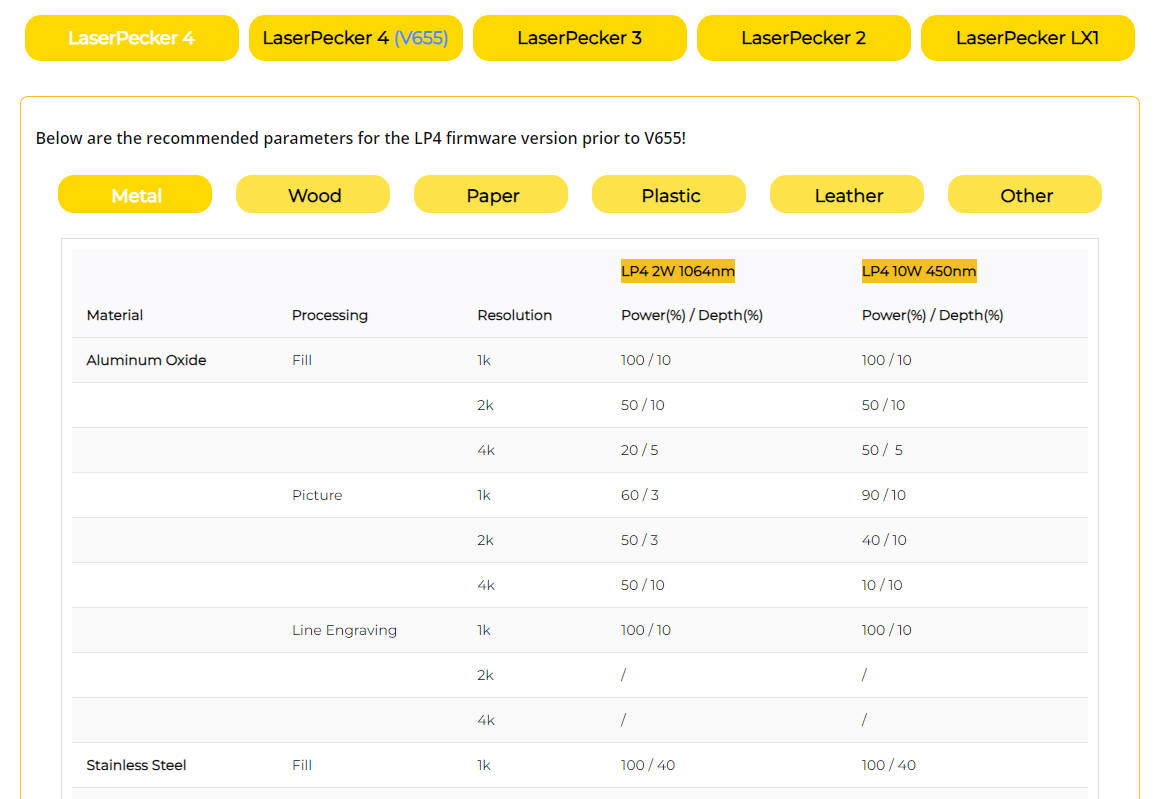

Fifth: In the software, adjust parameters such as power, speed, and resolution according to the type of wood and the complexity of the design. For best results, we recommend the following LP4 settings for laser cutting wood : 10 W diode laser; Resolution: 1k; Power: 80%; Depth: 80%; Passes: 3.

Further recommended settings for LaserPecker devices can be found in the table, valid for LP1 to LP5.

Step 5: Now cut the wood with a laser.

Check everything carefully to avoid mistakes. Then start the cutting process and watch as the laser brings your design to life.

When working with the wood laser engraving machine, wear safety glasses or use a cover to protect your eyes and body from possible damage caused by the blue laser.

Also, be aware that cutting can produce smoke or toxic gases. Wear a mask or use an air purifier for safety.

Conclusion

In summary, laser cutting of wood offers high precision and versatility, transforming wood into intricate designs and functional products with clean edges. It opens up endless possibilities for artistic expression, industrial manufacturing, and personal projects.