The art of brass laser engraving, also known as laser engraving of brass, is a precise technique for permanently engraving designs, text, patterns, or images onto brass surfaces such as coins, plaques, or lighters. This process uses the concentrated power of light to selectively remove material, leaving a permanent laser engraving on brass.

In this guide, we delve deep into the world of brass laser engraving, explaining everything from the basics to practical applications. Join us on this exciting journey!

In this article:

- Part 1: What is brass laser engraving and what machines are available?

- Part 2: Advantages of laser engraving brass

- Part 3: The 3 best creative ideas for laser engraving on brass

- 💡 Practical example: Engrave a brass coin in 5 steps

Part 1: What is brass laser engraving and what machines are available?

1.1 How does laser engraving on brass work?

In brass laser engraving, a focused laser beam is directed at the brass surface, causing local heating and vaporization of the material. This removes a thin layer of the brass, creating a precise laser engraving.

Of all engraving methods, laser engraving on brass is the best choice, as it allows for convenient, precise, and durable engraving on various types of brass. This allows for the creation of detailed designs with high durability.

1.2 Which machine is required for brass laser engraving?

To begin laser engraving brass, you'll need a suitable laser engraving machine . These machines are essential for laser engraving brass because they can handle the hardness and density of the material, ensuring precise and durable results.

Given the variety of laser engraving machines available, many people ask: Which laser is best for engraving brass? or Which machine is optimal for laser marking brass?

While CO₂ lasers are often considered powerful, there are occasional concerns about the suitability of diode lasers for laser engraving on brass. But don't worry: you can certainly engrave brass with a diode laser. Both diode and CO₂ lasers are suitable for home use and smaller engraving projects. If mobility, ease of use, and cost-effectiveness are paramount, a diode laser is the best choice for laser marking brass.

Part 2: Advantages of laser engraving brass

Brass laser engraving offers numerous advantages and is the preferred method for creating intricate designs on brass surfaces. Here are some of the key benefits:

- Finest details and highest precision:

Laser engraving brass allows for extremely fine and detailed patterns to be created on the surface – with a level of precision almost impossible to achieve with conventional engraving techniques. Even complex designs can be transferred to the material with razor-sharp detail.

- Gentle processing without material distortion:

Unlike traditional engraving methods, which often require direct contact with the material, laser engraving of brass is a non-contact process. This minimizes the risk of damage or distortion and ensures clean, precise engravings.

- Versatility for different material thicknesses:

Brass laser engraving can be adapted to various material thicknesses—from thin sheet metal to solid plates and curved surfaces. This flexibility opens up numerous application possibilities, from decorative engravings to functional markings.

Part 3: The 3 best creative ideas for laser engraving on brass

Here are three inspiring ways you can creatively use brass engraving (laser):

1. Laser-engraved brass coins:

Custom-designed brass coins are perfect for personal gifts or collectibles. Names, dates, or special messages can be permanently immortalized by laser engraving them into brass. Whether for collectors, promotional purposes, or as keepsakes, precise engraving ensures a high-quality appearance and longevity.

2. Laser-engraved brass plaques:

Whether as an award, commemorative plaque, or decorative sign, engraved brass plaques are versatile. Laser processing of brass allows for both detailed patterns and crisp text, creating elegant and customizable designs for a wide range of applications.

3. Laser engraved brass lighters:

A fine brass lighter becomes a unique gift or collectible with a personalized engraving. Laser engraving allows initials, logos, or artistic patterns to be applied to the lighter—ideal for adding a stylish, personal touch.

💡 Practical example: Engraving a brass coin in 5 steps

Preparation checklist for laser engraving a brass coin:

- Engraving material: brass coin

- Engraving machine: Laser engraver

- Engraving design: text, images, patterns, etc.

Is brass suitable for engraving? Absolutely! Whether you prefer patterns, quotes, or images, laser engraving brass is a simple and effective way to apply personalized designs to durable brass objects. Follow these five easy steps to create your custom laser engraving project.

Step 1: Choose the right brass material

Selecting the right material is crucial for optimal engraving results. Brass with a smooth and clear surface is best suited for precise laser engraving. Important: Make sure the material you use is safe for laser processing to avoid potential risks.

In this guide, we will show you how to successfully complete the engraving process using a brass coin.

Step 2: Choose the right laser engraving machine for brass

For this example, we are using the LaserPecker 4 (LP4) , a powerful dual laser engraver with versatile features that is ideal for laser marking brass.

Step 3: Prepare your engraving design

Create or import your desired design in graphics software . Pay attention to size, shape, and details such as text or patterns. Careful preparation ensures precise, high-quality brass laser engraving.

Step 4: Set up the brass laser engraving machine

First, make sure your laser engraver is turned on. Then connect it to your computer or mobile device using the appropriate interface (USB, Bluetooth, etc.).

Next, open your graphics software and load the desired design.

Now activate "Preview Mode" to check whether the laser lens is correctly focused. There are two methods for this:

Method 1: If you are using the LaserPecker 4 (LP4), use a ruler to measure the distance between the brass surface and the machine – the recommended distance is 15 cm (150 mm).

Method 2: Check if the two red laser dots overlap. This indicates that the focus is optimal.

Now place the piece of brass in the designated work area and check the positioning of your design. If it doesn't fit, adjust the size and placement so the engraving hits the exact area you want.

Finally, adjust the laser settings in the software—including power, speed, and resolution—depending on the material and design complexity.

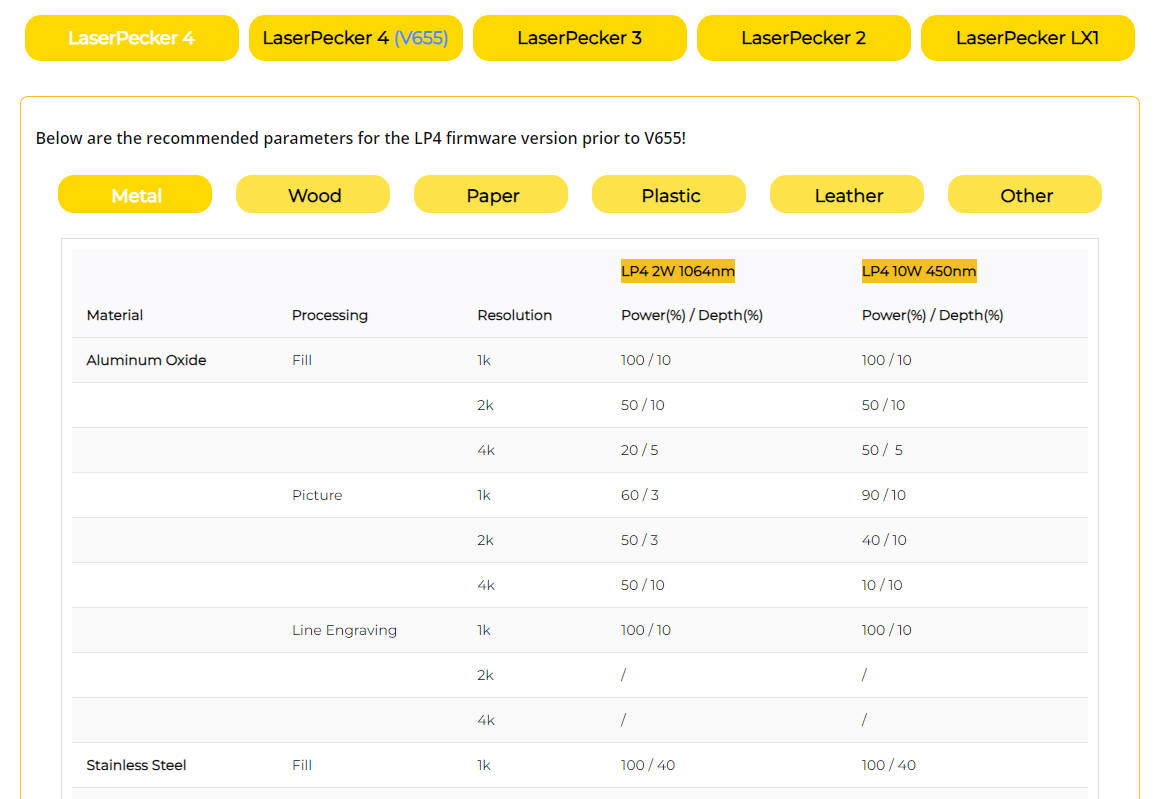

If you're wondering, "How much power do you need to engrave brass?" or "How deep can you laser engrave brass?", here are the recommended settings for the LaserPecker 4:

Power: 100%; Depth: 40%; Resolution: 1k; Laser: 10W, 450nm; Passes: 1

If you are looking for other laser marking brass settings for LaserPecker devices (LP1, LP2, LP3, LP4, LP5), you can find the complete overview in the material table on our website.

Step 5: Start laser engraving on brass

Double-check all settings to avoid mistakes. Then press start and watch the laser transfer your design to the brass surface!

When working with a 450 nm blue laser, you should wear safety goggles or use a laser safety shield to protect your eyes and skin.

Additionally, laser engraving brass can produce smoke or harmful fumes, so it's important to either wear a respirator or use an air purifier. If you want to learn more about using the LaserPecker 4, check out the LP4 user manual on our website!

Conclusion

This guide shows how easy and creative laser engraving on brass can be. This technique opens up exciting possibilities for personalized designs—from artwork to custom engravings on brass objects. Let your creativity run wild and bring unique ideas to life with laser engraving on brass!