Laser engraving on marble is a modern technique that allows you to create designs, texts and artworks with unparalleled precision and detail on marble floors, slabs or objects.

Unlike traditional engraving methods, which can be time-consuming and labor-intensive, laser engraving offers a clean, efficient and highly customizable approach.

In this guide, we explain how laser engraving on marble works, which machines are used, and why lasers are the ideal tool for beautiful, long-lasting designs.

This article contains:

Part 1: Overview of laser engraving on marble

1.1 What is marble laser engraving?

Laser engraving on marble is a state-of-the-art method for engraving designs, texts and artworks with exceptional precision and fine detail onto marble floors or slabs – or even creating a 3D embossing effect on stone .

1.2 How does laser engraving work on marble?

Laser engraving removes a thin layer of the marble surface through thermal ablation. The high-energy laser beam heats the marble, creating micro-fractures and vaporizing the top layer, resulting in a permanent engraving. This process does not rely on chemical reactions, making it suitable for natural stone and preserving its durability.

Because the laser beam is controlled by computer software, even complex and intricate designs can be engraved with high accuracy.

1.3 Why engrave on marble?

The applications of laser engraving on marble are extremely diverse and include:

Personalized Gifts: Engraved marble items make excellent personalized gifts for weddings, anniversaries, birthdays, or other special occasions. Names, dates, and meaningful messages can be artfully engraved into the marble surface, for example, to serve as decorative pieces or wall hangings.

Interior design: Engraved marble tiles or slabs can be used for walls, floors, and even furniture such as countertops, tabletops, or cabinet doors. The personalized pattern engravings lend a unique and luxurious atmosphere to any room.

Memorials: Laser engraving technology makes it possible to create artistic patterns, portraits, and inscriptions on memorial plaques and gravestones. A heart carved from polished marble, engraved as a memorial stone or grave ornament, is the most dignified way to commemorate a deceased person.

Artistic creation: Artists can unleash their imagination and create breathtaking works of art using laser engraving as a modern technology.

Durability: The patterns engraved on marble are very durable and not easy to fade, so they can retain their beauty for many years.

1.4 Marble engraving machine/tool

To engrave marble with a laser, you need a laser engraver, which is crucial for an efficient engraving process and precise results. Various laser engraving machines are available on the market (such as diode lasers, CO2 lasers, or fiber lasers), and many people ask: "Which laser is best suited for laser engraving marble?" or "What tools do I need to engrave marble?"

It really depends on your engraving needs. For home or small marble laser engraving projects, a diode laser engraver like the LP5 is a good choice. These marble laser engraving machines are easy to use and budget-friendly.

Why lasers are ideal for engraving on marble

Laser engraving offers several advantages over traditional engraving methods, making it the perfect choice for marble projects.

① Precision and attention to detail

Lasers can create fine lines, complex patterns, and even photorealistic images that are difficult or impossible to achieve with manual tools. Computer-controlled movement ensures consistent accuracy across the entire surface.

2. Speed and efficiency

Compared to chiseling or sandblasting, laser engraving is significantly faster. Complex designs that would take hours by hand can be completed in minutes – ideal for personal projects and commercial production.

③ Non-contact and minimal damage

Because the laser does not physically touch the marble, there is only a minimal risk of cracking or chipping. This non-contact process preserves the integrity of the marble while producing clean, precise engravings.

4 Versatility

Lasers can engrave various types and colors of marble and can be programmed for a wide variety of designs. Whether text, logos, or detailed works of art – lasers handle it all efficiently.

⑤ Reproducibility

Once programmed, designs can be perfectly replicated multiple times. This is particularly valuable for the mass production of plaques, tiles, awards, or decorative objects.

4. Shelf life

The patterns engraved on marble are very durable and not easy to fade, so they can retain their beauty for many years.

💡 Case study: Engraving marble cubes with a laser in 5 steps

Preparation list for laser engraving on marble:

- Engraving material: Marble cube

- Engraving machine: Diode laser engraver

- Engraving design: name, logo, images, patterns, etc.

Can marble be laser engraved? Yes! The process is straightforward. How long does it take to engrave marble? Don't worry – simply follow these 5 easy steps to receive your engraved marble object within a few hours!

Step 1: Choose your material – Marble cubes

Choosing the right material is crucial for achieving a perfect engraving. Different materials require different laser settings to ensure precise engraving. In this case study, we are engraving a portrait of Zeus onto a marble cube.

Step 2: Choose the right laser engraving machine for marble

We recommend the LaserPecker 5 (LP5) with a 20W 450nm diode laser and a speed of up to 10,000 mm/s – ideal for precise marble engravings.

Step 3: Prepare your engraving design

Use a LaserPecker design app/software or other graphics programs like Photoshop to create or import your desired design. Pay attention to size, shape, and details.

*Also visit LaserPecker CraftZone for inspiration or to purchase design files online.

Step 4: Set up the laser engraving machine for marble

First: Make sure the engraving machine is switched on and connected to your computer or mobile device (WiFi, USB, Bluetooth, etc.).

Second: Open LaserPecker Design Space and upload your design. (Formats such as JPG/PNG/G-code/SVG are all acceptable)

Source: LaserPecker CraftZone

Third: Place the material in the designated work area, activate preview mode, and ensure the laser is properly focused.

Fourth: Check that the design fits correctly on the marble. If necessary, adjust the size and position.

Finally: Adjust the laser parameters in the software, such as power, speed, and resolution, according to the marble's properties and the complexity of the design. How much laser power is needed for marble engraving? Don't worry, here's the recommendation:

For best results, we recommend the following LaserPecker LP5 settings for marble: 20 W 1064 nm diode laser; Resolution: 4K; Power: 100%; Depth: 20%; Mode: 3D grayscale relief

When operating a laser engraving machine, you should wear safety glasses or use laser protection to protect your eyes and body, as the blue laser can be dangerous.

Please note that smoke or toxic gases may be produced during the engraving process. Wearing a mask or using an air purifier is recommended for safety.

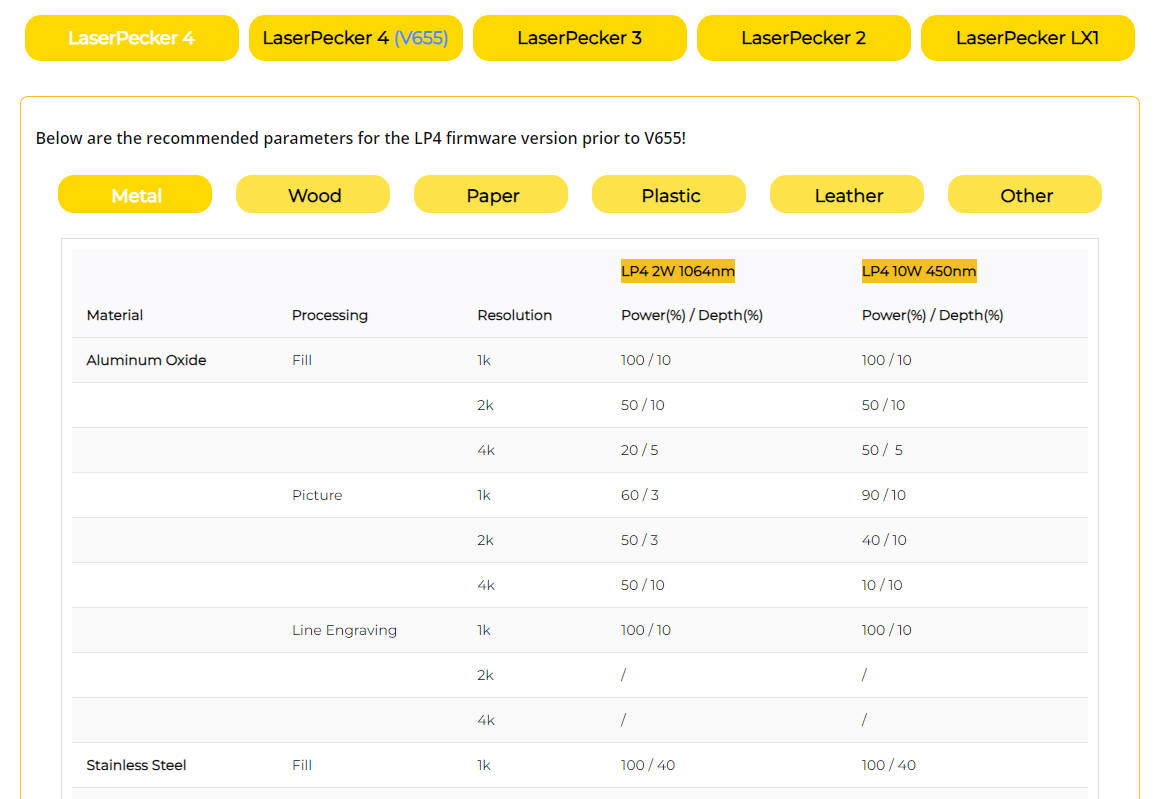

Further recommended LaserPecker engraving and cutting parameters for all LaserPecker devices (LP1, LP2, LP3, LP4, LP5) can be found in the linked table.

Step 5: Now start the laser engraving on your marble.

Double-check everything to avoid mistakes. Then press start and watch as the laser brings your design to life. Simply monitor – and you're done!

Conclusion

Laser engraving has revolutionized the possibilities for personalizing marble, combining speed, precision, and versatility in a single process. Whether decorative objects, personalized gifts, or portraits, with the right equipment and technique, you can achieve clean, precise, and reproducible results. This allows everyone—from beginners to experienced craftspeople—to unlock the full potential of laser engraving on marble.