The art of laser engraving on fabric – also known as laser marking or laser etching – uses precise laser beams to create detailed designs and patterns on textile surfaces.

In this comprehensive guide, we take an in-depth look at textile laser engraving . From a basic understanding of the process to proper material preparation and concrete implementation steps – you'll find all the important information at a glance.

Before you start your own textile laser engraving project, we recommend that you read this guide carefully.

In this article:

Part 1: What is textile laser engraving and which machines are used?

1. Introduction to textile laser engraving

"Can you laser engrave fabric?" - Absolutely! Laser engraving on fabric works by directing a focused laser beam onto the surface of the material. Targeted heat vaporizes a thin layer of material, allowing text, graphics, or patterns to be precisely engraved into the fabric.

This method impresses with its high precision and versatility—ideal for personalized projects such as custom-designed jeans or T-shirts. Laser engraving of textiles opens up entirely new creative possibilities in the textile sector.

2. Which machine is needed?

Anyone who wants to get into textile laser engraving – for example to design T-shirts, jeans or other fabrics – needs a laser engraving machine that is specifically designed for textile materials.

So, which is the best laser engraving machine for fabric? A popular model is the LaserPecker series. It is characterized by user-friendly operation, precise engraving performance, and compatibility with a wide range of materials, including fabric.

Part 2: How to properly prepare materials for laser engraving?

- Cotton:

Cotton is a natural material and ideal for laser engraving fabric. It absorbs laser energy well and delivers clean engraving results.

- Polyester:

Synthetic materials like polyester can also be engraved without any problems. Many people ask, "Can you laser engrave 100% polyester?" – Yes, it is possible. However, it is important to conduct tests beforehand and choose the correct laser settings to achieve optimal results.

- Denim (jeans fabric):

Thanks to its robust structure, denim is ideal for detailed laser engraving on fabric. This is a particularly popular application for personalized jeans or fashion accessories.

- Felt:

Felt is soft, flexible, and can be engraved with exceptional precision. Perfect for creative craft projects or decorative DIY applications.

- Silk:

Despite its delicate nature, silk can be engraved with delicate patterns and designs. Laser engraving on textiles lends garments and accessories a sophisticated, individual touch.

- Linen:

Linen boasts a natural texture and durability. With the right laser technology, unique engravings can be created on linen—ideal for personalized home textiles or clothing.

💡 Practical example: In just 5 steps to perfect laser engraving on fabric

Is fabric difficult to engrave? Not at all! Whether patterns, quotes, or images – with the right preparation, textile laser engraving is simple and effective. In just five steps, custom designs can be precisely applied to fabric surfaces.

Step 1: Choose the right fabric material

Choosing the right fabric is crucial for a successful engraving result. Pay attention to the material's composition, texture, and color—these properties influence how well the material is suited for laser engraving on fabric.

Popular materials for laser engraving textiles include cotton, polyester, denim, leather, and canvas. Important: Be sure to use only laser-safe materials to avoid risks such as smoke or fire.

In this example we focus on laser engraving denim fabric.

Step 2: Choose the right laser engraving machine

Not every machine is suitable for fabrics. Make sure the machine is specifically designed for laser engraving fabric and covers a variety of applications.

Our recommendation: The LaserPecker 4 (LP4) , This model works with two laser types and is versatile – perfect for laser engraving textiles on T-shirts, jeans or other materials.

Step 3: Prepare the design

Create or import your desired motif using a Graphics software . You should consider size, shape and details such as lettering or fine patterns to get the most out of your laser engraving on textiles.

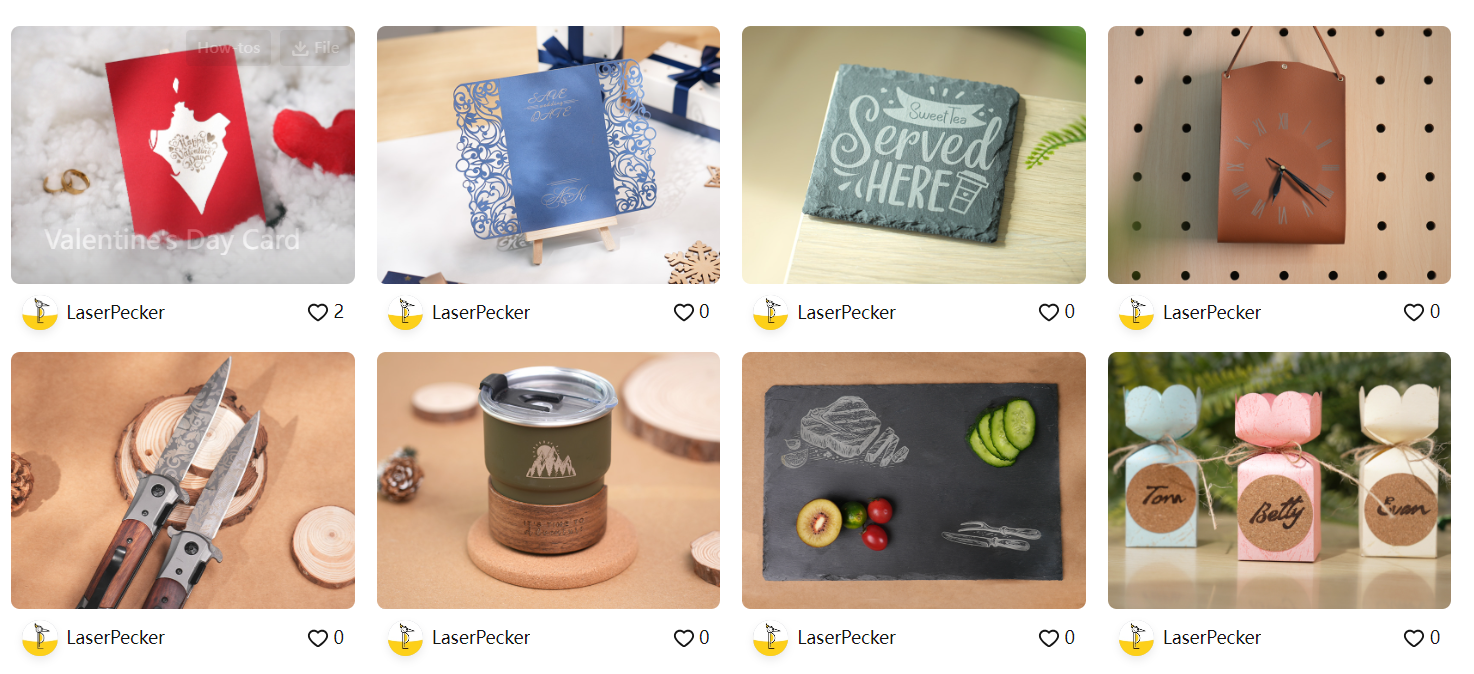

Are you lacking a brilliant idea? In our CraftZone, you'll find a wide selection of creative templates and inspiration for laser engraving fabrics and other materials.

Step 4: Set up the textile laser engraving machine

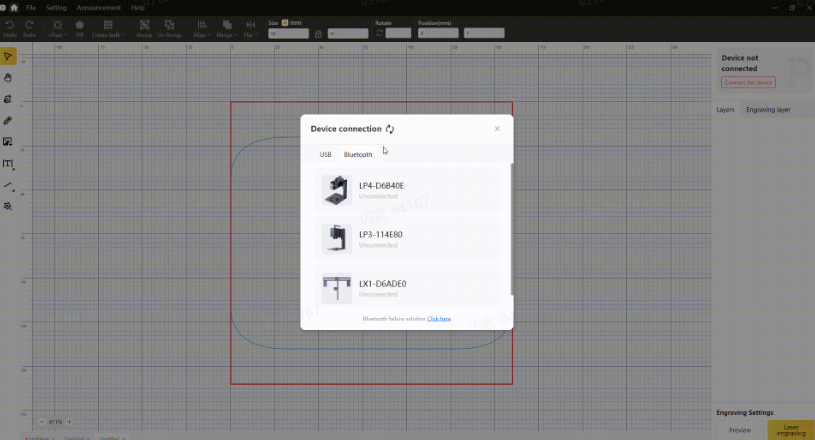

First, make sure your engraving machine is turned on. Then connect it to your computer or mobile device via USB, Bluetooth, or another interface.

Now open your graphics software and load the desired design.

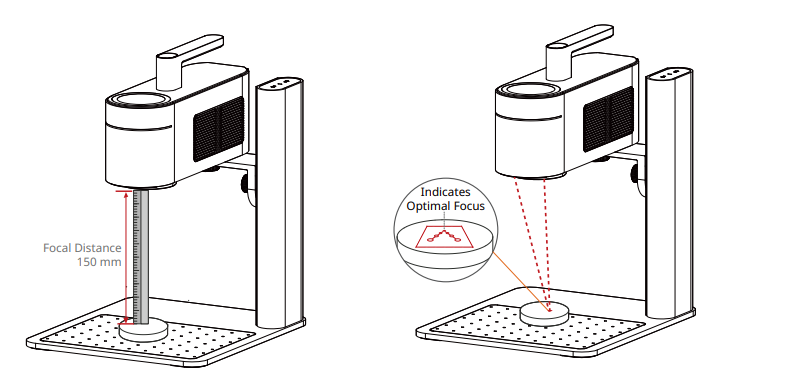

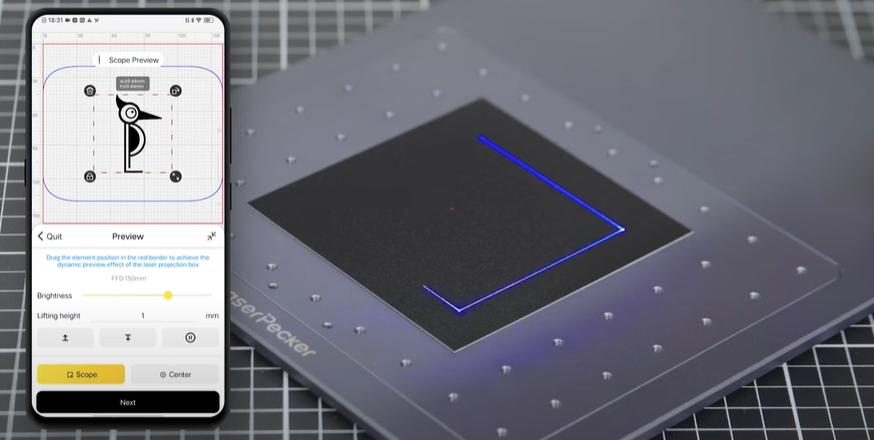

Next, turn on preview mode to check if the laser lens is correctly focused. There are two ways to check:

When using the LaserPecker 4 (LP4), you can either use a ruler to measure the distance between the denim fabric and the machine – a distance of 15 cm or 150 mm is recommended.

Or you can check whether the two red dots of the laser overlap. If they are exactly aligned, the focus is optimal—an important prerequisite for precise laser engraving on fabric.

Next, position the fabric correctly in your work area and check that the design is displayed correctly on the denim. If necessary, adjust the position and size of the motif so that everything is perfectly aligned with your project.

Now it's time to adjust the laser engraving settings: Adjust parameters such as power, speed, and resolution according to the fabric type (e.g., jeans) and design complexity.

You may be wondering: “How much laser power does it take to engrave jeans?” “How deep does the engraving go on jeans?” Here are our recommended settings for laser engraving textiles with the LP4:

Wavelength: 1064 nm

Performance: 70%

Resolution: 1k

Engraving depth: 5%

Rounds: 1

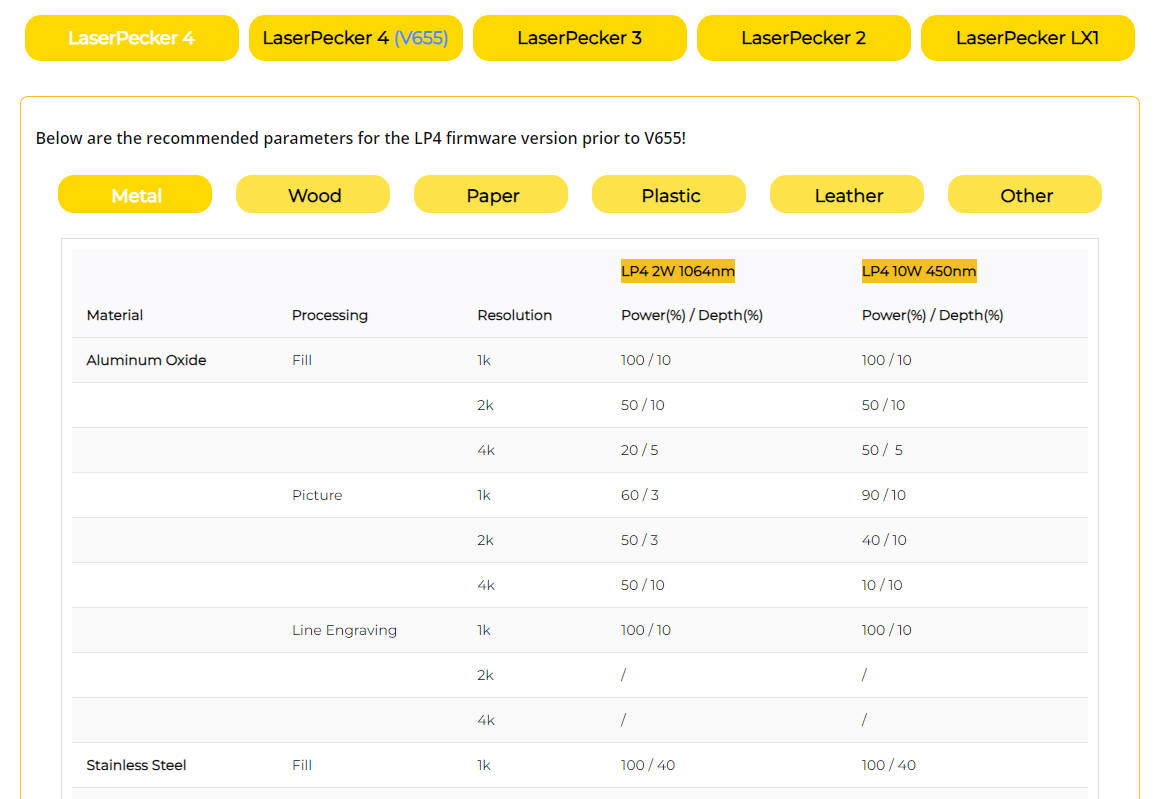

If you are looking for other laser marking brass settings for LaserPecker devices (LP1, LP2, LP3, LP4, LP5), you can find the complete overview in the material table on our website.

Step 5: Start your fabric engraving

Check everything carefully one more time – then you're ready to go! Click start and watch the laser bring your design to life on the fabric.

Safety is particularly important when laser engraving textiles:

1. When using a 450nm blue laser, you should always wear protective goggles or use a laser safety shield to protect your eyes and body.

2. Remember that engraving fabrics can produce smoke or even toxic gases – a respirator or air purifier is recommended.

Project ideas: The 3 most creative applications for laser engraving on textiles

Laser engraving textiles opens up exciting possibilities for customizing clothing and accessories. Here are three particularly creative ideas for customizing fabrics with a laser:

1. Laser engraved jeans / denim:

Laser engraving on fabric transforms jeans into truly unique pieces. Whether detailed patterns, personalized messages, or photorealistic motifs – denim's texture makes it ideal for impressive engraving.

2. Laser-engraved fleece sweaters:

Fleece is not only comfortable to wear but also ideal for laser engraving on textiles. This allows you to enhance plain sweaters with creative engravings – ideal for personalized gifts or limited-edition collections.

3. Fleece blankets and hoodies:

Whether for home or as a promotional gift, laser-engraved fabric transforms fleece blankets and hoodies into real eye-catchers. Logos, names, or custom designs make each piece unique.

Conclusion

This tutorial has demonstrated how versatile and creative textile laser engraving can be. With the right technique, simple fabric materials can be transformed into unique works of art.

We hope this article inspires you to create your own laser engraving projects on fabric – there are no limits to your creativity!