“Has anyone ever engraved a golf ball with a laser?”

Golf balls are an essential piece of golf equipment, designed for optimal flight and performance. Each golf ball consists of a core, a cover, and a dimple pattern that influences its speed and trajectory.

When it comes to laser engraving golf balls, it often refers to engraving your own name, custom designs, logos, or other text onto the surface of the golf ball.

In this guide, we'll take a closer look at laser engraving golf balls—how it works, the benefits, and how to create your own custom engraved golf balls step by step. Let's dive into this exciting topic together!

In this article:

- Part 1: What is laser engraving of golf balls and which machine is used for it?

- Case study: Laser engraving a golf ball in 5 steps 💡

Part 1: What is laser engraving of golf balls and which machine is used for it?

1.1 How does laser engraving on golf balls work?

As mentioned above, laser engraving golf balls refers to the process of engraved designs, logos, or text onto the surface of the ball. Golf balls are typically made of urethane, ionomer, or Surlyn covers—materials valued for their durability, spin control, and performance.

Engraving is done using a high-precision laser beam that transfers controlled heat to the surface without affecting the ball's structure. This creates permanent and detailed markings without the need for ink or adhesives. This method is therefore ideal for personalizing golf balls with logos, names, or custom patterns.

1.2 Laser engraving machine/tool for golf balls

To engrave golf balls, a laser engraver is required. This tool is crucial for achieving precise and durable engravings on the surface of the ball. It ensures accuracy and efficiency, making the personalization process particularly smooth.

Since there are various laser engraving machines available, the question arises: Which laser is best for engraving golf balls? or Which machine do I need to engrave golf balls?

For home use or smaller engraving projects, diode laser engravers are an excellent choice. They offer mobility, ease of use, and cost savings—ideal for personalizing golf balls with names, logos, or custom designs.

1.3 Why are lasers ideal for engraving golf balls?

Compared to traditional marking methods, lasers offer distinct advantages when engraving golf balls. From superior precision to consistent quality, here are the key reasons why laser technology stands out:

Precision without contact

Unlike mechanical engraving, the laser does not directly touch the ball. This prevents deformation or surface damage – crucial for maintaining the ball's balance and playing characteristics. With accessories like the Rotary Extension , golf balls can also be engraved from any angle with excellent results.

Fast personalization

Traditional engraving or pad printing are slower and often require manual setup for each new design. Lasers, on the other hand, can change designs instantly, enabling faster production and flexible on-demand customization.

Consistent quality in series

Ideal for mass production – every engraving is identical, ensuring professional, consistent branding or personalized design.

No consumables or high maintenance costs

Conventional processes require inks, stencils, or cutting tools that need to be replaced regularly and are often messy. Laser engraving is cleaner, low-maintenance, and cost-effective in the long run.

💡 Case study: Laser engraving a stainless steel golf ball in 5 steps

Preparation checklist for laser engraving golf balls:

- Engraving material: golf ball

- Engraving machine: Laser engraver

- Engraving design: name, logo, pictures, patterns, etc.

Is laser engraving golf balls difficult? No! The process is straightforward. So, how do you engrave golf balls? Don't worry—just follow these 5 easy steps to add personalized, detailed designs to your custom engraved golf balls.

Step 1: Select material – plastic golf ball

Choosing the right material is crucial to achieving optimal engraving results. Different materials require specific laser settings to ensure precise engraving. It's also important to ensure the golf ball's material is laser-compatible to avoid potential safety risks.

In this guide, we will conduct a case study: engraving a name on a plastic golf ball.

Step 2: Choosing the right laser engraving machine for golf ball engraving

Here we choose the LaserPecker 4 (LP4) – a dual-laser and multifunctional laser engraver that is particularly suitable for engraving plastic golf balls.

* Alternative

If you want to achieve a higher engraving speed and an even better result on plastic surfaces, you can also upgrade to a more powerful laser engraver such as the LP5 .

Step 3: Prepare your engraving design

Use a LaserPecker graphic design app or software to create or import the desired image, or enter the text you want to engrave on the surface of the golf ball. Pay attention to size, shape, and details such as font or pattern.

Step 4: Set up the golf ball laser engraving machine

① First, make sure your engraver is turned on, and then connect your laser engraver to your computer or mobile device via the appropriate interface (USB cable, Bluetooth, etc.).

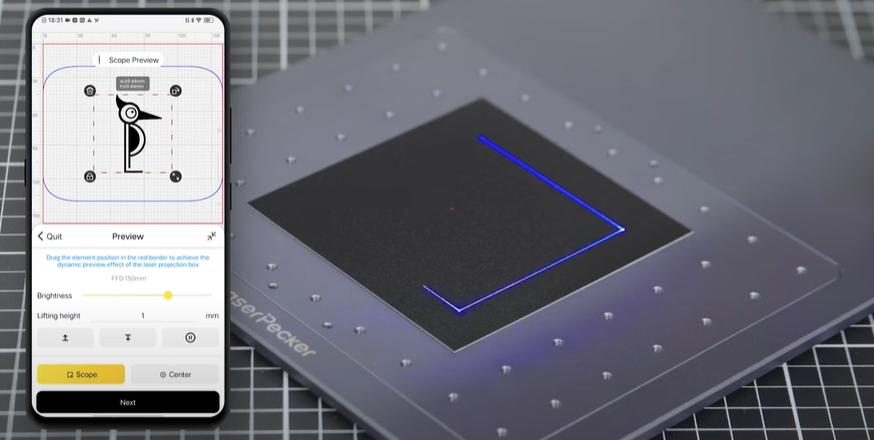

② Then open the graphic design app or software and upload your design

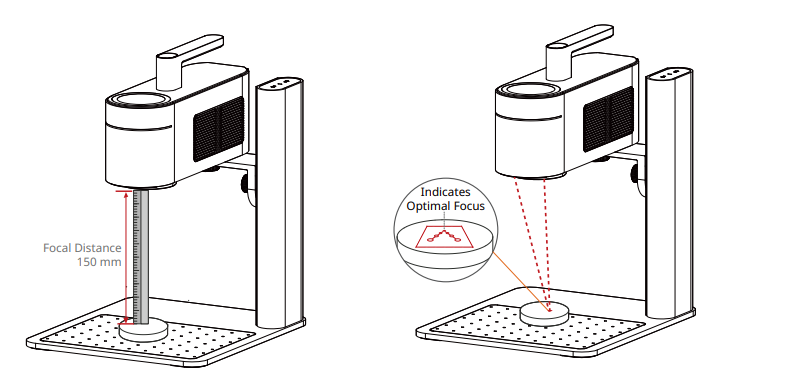

3. Turn on "Preview Mode" to check if the laser lens is correctly focused. Correct focus of the laser engraving machine is crucial for achieving high-quality engraving!

4 Fourth, you need to place the items within the designated work area and check the appearance of the design on the golf ball. If it doesn't fit properly, you need to adjust the position and size to ensure it matches the dimensions of your project.

5 Finally, access the software's laser settings to adjust parameters like power, speed, and resolution according to the golf ball's characteristics and the complexity of the design. You may be wondering, "How much laser power is needed to engrave a golf ball?" Don't worry, I've got you covered!

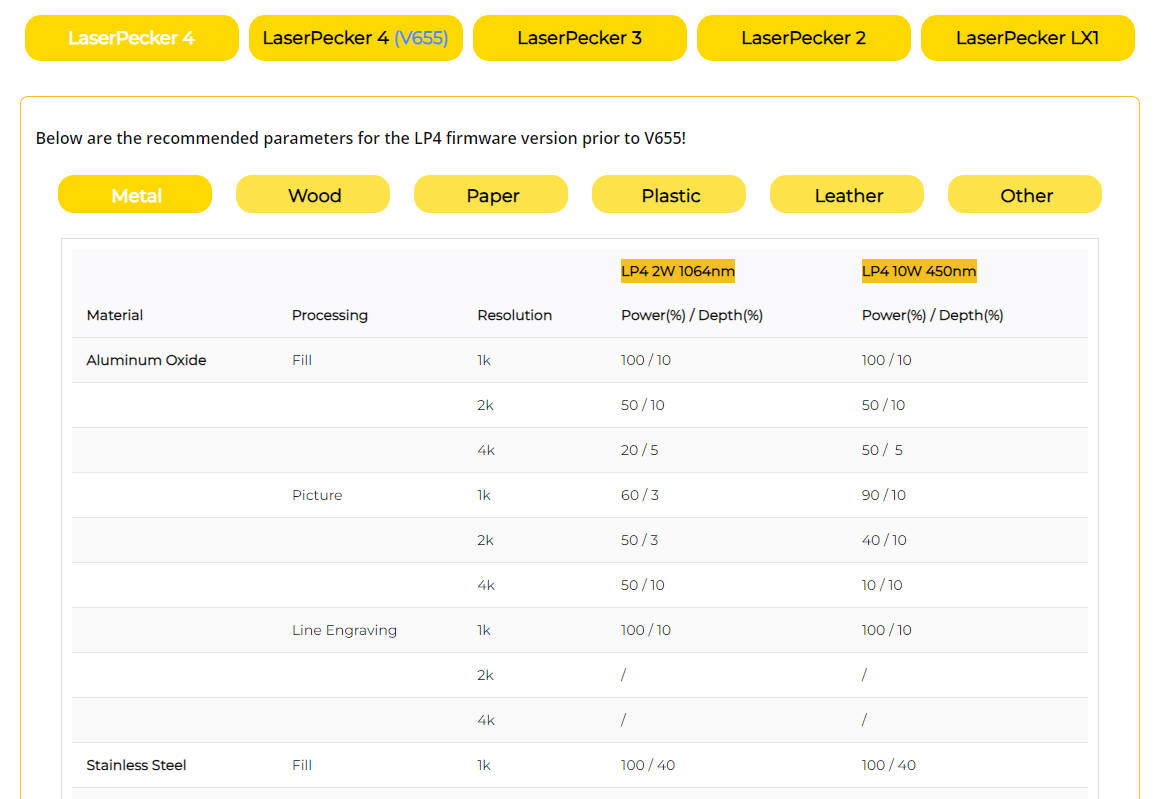

For best results, the recommended material settings for the LaserPecker 4 when engraving a golf ball are: 2W, 1064nm; Resolution: 2K; Power: 100%; Depth: 60%; Pass: 1.

To explore more recommended LaserPecker engraving and cutting parameters, see the settings table that applies to all LaserPecker machines, including LP1, LP2, LP3, LP4 and LP5.

Step 5: Start laser engraving your golf ball now

Double-check everything to avoid mistakes. Then press the start button and watch the magic happen. The laser brings your design to life. Keep an eye on the process, and you're done!

Please also note that smoke or toxic gases may be generated during the laser engraving process. Wearing a mask or using an air purifier is essential for safety.

Conclusion

In summary, laser engraving offers unparalleled precision and quality when it comes to personalizing golf balls. Whether you're engraving golf balls with names or applying logos and designs to the surface of the golf ball, the process ensures durability and clarity without compromising the ball's performance.

In addition, laser engraving with advanced features such as adjustable focus and special accessories offers the perfect solution for creating unique, high-quality engraved golf balls.

Ready to create your own custom engraved golf balls with names? Try the LaserPecker 4 today and take your engraving game to the next level!